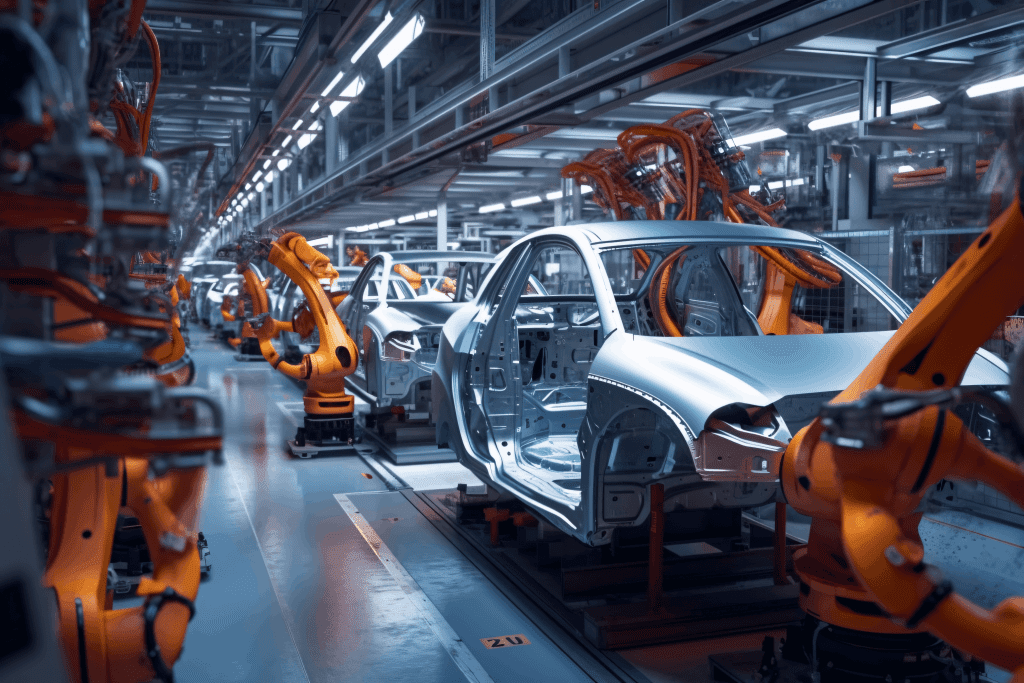

North American Automaker Supercharged Engine Testing to Fuel Up Vehicle Production

Please fill the below form

America’s leading automotive manufacturer sought to optimize its engine testing operations to meet increased vehicle production demands cost-effectively. Their requirements included:

- Optimized testing equipment usage

- Reduced inefficiencies

- Real-time data analysis, resulting in accuracy and speed of operations.

They partnered with 12th Wonder to reap the benefits of Engine Portal, a custom software solution for process digitization and optimization. This case study delves into their experience and results, showcasing how Engine Portal streamlined their testing infrastructure, boosted productivity, and assisted in achieving their goals.

- Cost-effective scaling of engine testing aims to match increased vehicle production demand in today's market conditions

- Accelerate engine testing for faster time-to-market.

- Scaling engine testing processes to match production demands for expanded engine model selection.

- Unifying multiple data points through digital solutions to enhance efficiency and accuracy.

- Digitizing engine testing processes to eliminate errors and delays resulting from traditional manual testing.

- Improved efficiency

- Saving 350 hours per year per test module

Accelerating Towards

a Turbocharged

Digital Future

a Turbocharged

Digital Future

“Our engagement with 12th Wonder has been invaluable in developing Reliable Fuel-Efficient Engines on schedule. 12th Wonder’s flexibility to support the development has been outstanding. I look forward to continuing our partnership as the Engine Portal evolves”

Team lead of America’s leading Automotive Manufacturer